Established in 2011. With three decades of experience, LEM Contracting has a stellar record of proven construction projects across India.

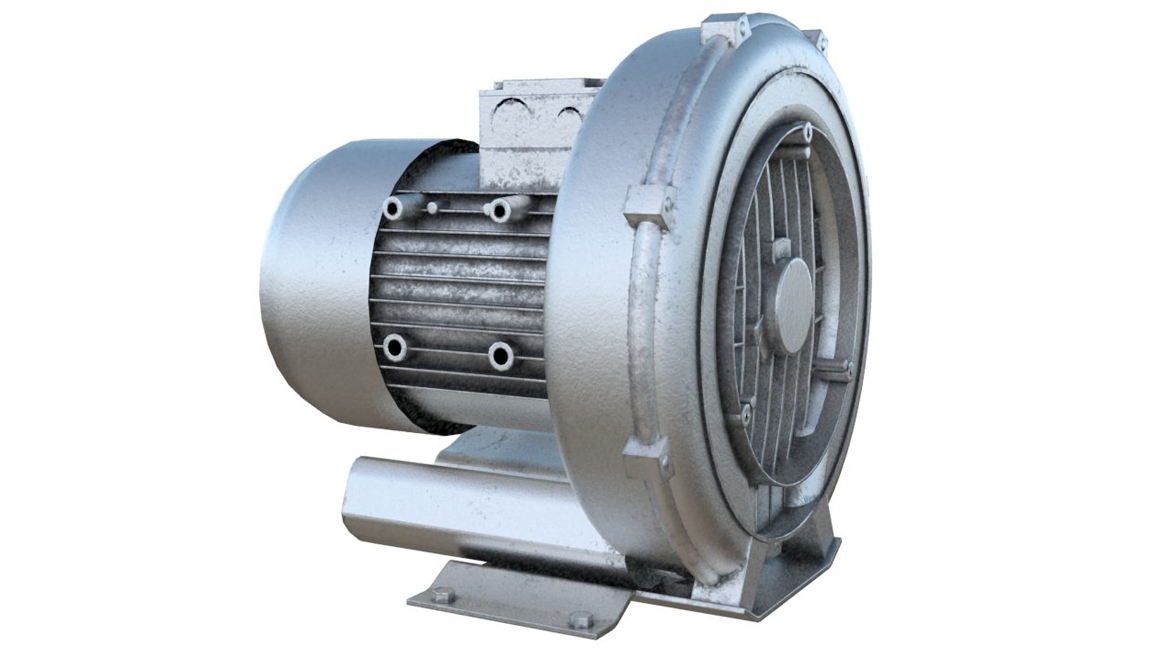

LEM Contracts has over 15 years of industry existence (estd:2011) and is today identified as a customer-focused firm with excellence in all its major lines of contracting business, including Plumbing & Sanitation, Fire Alarm & Detection, Water Treatment Plants, Fire Fighting, S.T.P/E.T.P., Compressed Air, Gas & Steam Piping, Rain Water Harvesting, Swimming Pool Filtration Plants, Allied Civil Works, Material supply related to construction and mechanical works, Manpower supply for mechanical and constructions works, Manufaturing product like Storage Tank Manufacture and AGITATOR Storage Tank and Vessel, Scrubber, Lids, Lining of Equipments, Blower and more. It is also doing Industrial & Commercial repairing maintanence work.

The company was established in 2011 by a group of experts who has a wide range of experience

We have the pool of highly skilled and best candidates so we are in a position to meet your expectations

LEM Contracts is an expert in finding the right people for the right jobs. We work with our clients to meet their needs

We as a manufacturer of the PP rectangle tanks have paid significant emphasis on the durability and quality and for that have made it from the premium grade polyester and vinyl ester resins under the severe inspection of the quality analyst team. Our provided PP rectangle tanks are rust proof and embraces outstanding withstand capability against corrosive chemicals and high temperature that makes it a top choice for storage of any type of chemicals with no doubt. We manufacture these PP rectangle tanks in a wide variety of specifications and also provide as per the custom made specification stated as per the end user. Both types of PP rectangle tanks are assured for durability and longevity in highly corrosive context.

Our range of Spiral storage tanks is widely used for storing highly corrosive chemicals and pickling at high temperature. These are available in varied shapes and can also be customized as per requirement of the client.

Backed by our high-tech manufacturing facility, we are offering our clients an excellent quality array of FRP Chemical Storage Tank. These storage tanks are developed by team of professionals by using the high grade material and modern technology as per with market prevalent norms. Our offered storage tanks are provided in several stipulations as per the requirements the patrons within given time frame.

Stainless Steel Tanks are the perferred choice for commercial and residential applications. From the harshest industrial applications to the most secure storage of residential drinking water, Stainless Steel is unsupassed in safety and durability.

Using alloys such as 316Tyle L & 304, we offer single and doubled walled tanks that can meet all API Standards with Interior Coatings that meet all EPA and FDA Stadards for the Food Industry. All our Stainless Steel Tanks meet or exceeds NSF61, NFPA22, CBC2010, ACE#7 and AWWA, UL 142, API 650 for all storage tank applications.

We offer a wide variety of shapes and configurations as well as custom fabrication.

We are offering best quality MS Storage Tanks. MS Storage Tanks offered by us are manufactured by using latest machines, tools and high quality material sourced from the trusted vendors of the market. These MS Storage Tanks are light in weight and easier to hang. Best in quality, these Storage Tanks remain same up to longer years. Our quality checkers properly examine the entire product range to ensure the presence of high quality and optimality.

We manufacture a wide range of HDPE chemical reaction vessels that are manufactured using optimum quality imported Polyethylene. These HDPE reaction vessels are known for the following features such as:

We manufacture a wide range of PP chemical reaction vessels that are manufactured using optimum quality imported Polypropylene. These PP reaction vessels are known for the following features such as:

We manufacture a wide range of FRP chemical reaction vessels. These FRP reaction vessels are known for the following features such as:

We have the ability to offer reaction vessels that consists of MS structure that holds the vessel, agitator and gear box assembly.

Avail from us a wide gamut of PP FRP Nutche Filters. These Filters are appreciated by our clients, owing to their durability, high strength and precision engineering. We offer these in different capacities as suitable to the clients at market leading prices.

Our custom design FRP Industrial Scrubber is generally installed on chimneys or air exhaust systems to control pollution. These are made of high graded raw material with the help of sophisticated machines and latest technology.

We are a psecialist supplier of temporary and permanent pesonnel to the industrial, transport and technical marketplace. At industrial work solutions we pride ourselves on offering a personal service to work in conjunction with oyur own personnel department to offer service at the highest level.

We are introducing ourselves as a leading manufacturer of pickling tank for galvanizing-pickling plant for power transmission tower, pipe, tube, wire, strip, coil, bright bar etc. We will custom design and fabricate thermo plastic process equipment to meet specific needs such as tanks for pickling, degreasing, rinsing, flux, passivation, pre & post treatment, plating, cleaning and other acidic process. Fume extraction system for acid fumes / zinc fumes etc.

We hold immense expertise in catering to the variegated requirements of the customers by bringing forth a remarkable range of FRP Ducting. Meticulously manufactured utilizing optimum-grade raw material and other basic components, these products are developed in accordance with the industry set guidelines. Our range of products are further tested by our experts on various parameters to satisfy our clients.

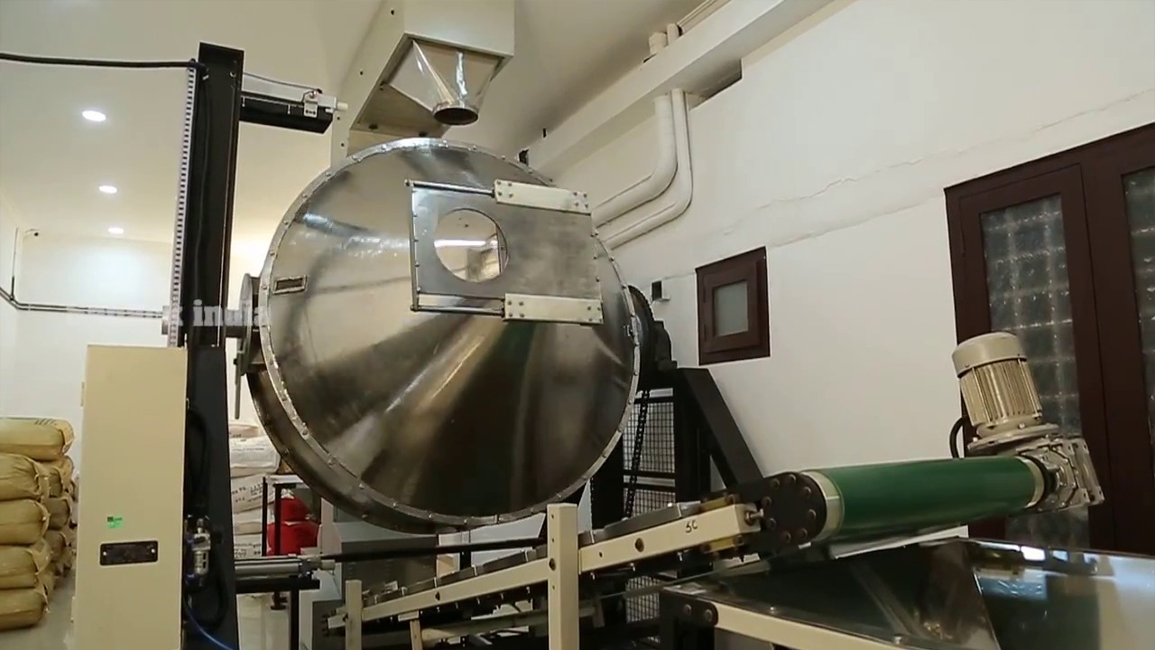

Proprietary internal mixing flights create the unique Jas blending action. The gravity driven process produces a rapid, thorough blend while imparting minimal energy and intensity to the product. This maximizes equipment life without sacrificing blend quality. The same blending action provides an ideal fluid bed for coating, impregnating and agglomerating. Continuous rotation throughout the entire blending cycle assures that all materials remain in motion and prevents segregation in batches of varying material densities.